In the intricate realm of precious metal metallurgy, the selection and utilization of chemical reagents play a pivotal role in determining the efficiency and effectiveness of the extraction and refining processes. Among these, sodium sulfite, a versatile inorganic compound, has emerged as a valuable asset, contributing significantly to various stages of precious metal processing. This blog post delves into the multifaceted applications of sodium sulfite in precious metal metallurgy, exploring its chemical properties, mechanisms of action, and practical implications.

Chemical Properties of Sodium Sulfite

Sodium sulfite is a white, crystalline solid that dissolves easily in water, creating an alkaline solution. Its chemical structure comprises two sodium components and one sulfite component, which gives it unique chemical reactivity. The sulfite part of sodium sulfite can act as a reducing agent, a complexing agent, and a pH regulator. These qualities make it a versatile reagent in various chemical processes, including those in precious metal metallurgy.

Applications in Precious Metal Metallurgy

1. Reduction Processes

One of the primary applications of sodium sulfite in precious metal metallurgy is in reduction processes. Precious metals like gold, silver, and platinum often exist in oxidized forms in ores or secondary materials. Sodium sulfite can effectively convert these metal oxides back into their metallic states. For example, when treating gold-containing ores, sodium sulfite reacts with gold oxides, helping to release gold in its pure form. The reaction works by the sulfite part giving electrons to the metal oxide, changing in the process. This reduction step is crucial for the following separation and recovery of precious metals.

2. Complexation and Solubilization

Sodium sulfite also functions as a complexing agent in precious metal metallurgy. It can form stable combinations with certain precious metal ions, increasing their solubility in water-based solutions. This property is especially useful in leaching processes, where the aim is to dissolve precious metals from their host materials. By combining with precious metal ions, sodium sulfite can boost the efficiency of leaching, leading to a higher extraction rate of valuable metals. For instance, when leaching silver from silver-bearing ores, the formation of these combinations improves the solubility of silver, making it easier to separate from the ore.

3. Purification and Refining

During the purification and refining of precious metals, sodium sulfite can play a crucial role in removing impurities. It reacts with certain impurities in the metal solutions, causing them to separate out. This selective separation helps achieve a higher purity in the final precious metal product. Additionally, sodium sulfite can be used to adjust the oxidation state of the solution, which is essential for controlling the state of different metal substances and ensuring the efficient separation of precious metals from other elements.

4. Environmental Considerations

In addition to its direct metallurgical applications, sodium sulfite also offers environmental benefits in precious metal processing. Compared to some other chemical reagents used in the industry, sodium sulfite is less toxic and more environmentally friendly. Its use can help reduce the production of hazardous waste and minimize the environmental impact of precious metal metallurgy operations. Moreover, the by-products formed during the reactions involving sodium sulfite are generally less harmful and can be managed more easily from an environmental perspective.

Advantages and Challenges

Advantages

The use of sodium sulfite in precious metal metallurgy brings several advantages. Its versatility as a reducing, complexing, and purifying agent allows for a more integrated and efficient processing approach. It can improve the extraction and recovery rates of precious metals, leading to higher yields and increased economic viability of metallurgical operations. Furthermore, its relatively low toxicity and environmental friendliness match the growing focus on sustainable and green metallurgy practices.

Challenges

However, the application of sodium sulfite also presents some challenges. Under certain conditions, sodium sulfite can change spontaneously, which may affect its stability and reactivity. Additionally, the formation of some combinations with metals may depend on the pH level of the solution, requiring careful control of the solution conditions to get the best results. Another challenge is dealing with the by-products generated during the reactions, although they are generally less hazardous compared to those from other reagents.

In conclusion, sodium sulfite is a valuable chemical reagent in precious metal metallurgy, with diverse applications in reduction, complexation, purification, and environmental protection. Despite the challenges associated with its use, ongoing research and technological advancements aim to further optimize its performance and expand its scope of application. As the demand for precious metals continues to grow, the role of sodium sulfite in ensuring sustainable and efficient precious metal metallurgy is likely to become even more significant in the future.

- Random Content

- Hot content

- Hot review content

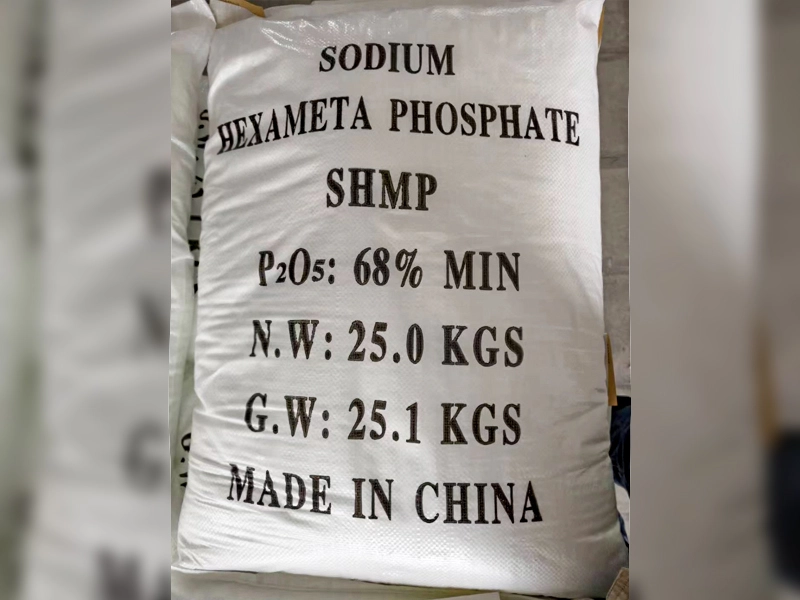

- Industrial grade sodium hexametaphosphate 68% SHMP

- Sodium Amyl Xanthate (SAX) 90%, Mining chemical, mining flotation reagent

- Dithiophosphate 25S

- Expanded AN explosive

- Ammonium Persulfate Industrial Grade 98.5%

- Antimonium Tartrate Potassium

- Feed Grade 98.0% Calcium Formate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: