In the realm of chemistry, both Potassium hydroxide (KOH) and Sodium hydroxide (NaOH), commonly known as caustic potash and caustic soda respectively, play significant roles. Despite sharing some similarities as strong bases, they possess distinct characteristics that set them apart in various aspects. This article aims to provide a comprehensive overview of the differences between potassium hydroxide and sodium hydroxide.

Chemical and Physical Properties

Molecular Structure and Composition

Potassium hydroxide consists of one potassium (K) atom, one oxygen (O) atom, and one hydrogen (H) atom, with the chemical formula KOH. Sodium hydroxide, on the other hand, is composed of one sodium (Na) atom, one oxygen atom, and one hydrogen atom, expressed as NaOH. The difference in the metal cation (potassium vs. sodium) is fundamental and contributes to many of their varying properties.

Physical Appearance and Solubility

Both compounds are white, hygroscopic solids at room temperature, readily absorbing moisture from the air. However, they exhibit differences in solubility. Potassium hydroxide is highly soluble in water, releasing a significant amount of heat during dissolution, which can cause the solution to become very hot. It is also soluble in ethanol and methanol. Sodium hydroxide is equally soluble in water, accompanied by a notable exothermic reaction. But comparatively, potassium hydroxide generally has a higher solubility in certain organic solvents, making it a preferred choice in some specialized chemical processes.

Melting and Boiling Points

Potassium hydroxide has a melting point of approximately 360 °C (680 °F) and boils at around 1.324 °C (2.415 °F). Sodium hydroxide, conversely, has a slightly higher melting point of about 318 °C (604 °F) and boils at 1.388 °C (2.530 °F). These differences in melting and boiling points can influence their use in high-temperature applications, with each being selected based on the specific temperature requirements of a process.

Preparation Methods

Industrial Production of Potassium Hydroxide

Industrially, potassium hydroxide is mainly produced through the electrolysis of potassium chloride (KCl) solutions, a process known as the chloralkali process. In this method, an electric current is passed through a potassium chloride solution in an electrolytic cell. At the anode, chloride ions are oxidized to form chlorine gas, while at the cathode, water is reduced, producing hydrogen gas and hydroxide ions. The potassium ions combine with the hydroxide ions to form potassium hydroxide.

Industrial Production of Sodium Hydroxide

Sodium hydroxide is also produced via the chloralkali process, but using sodium chloride (NaCl) as the starting material. Similar to the production of potassium hydroxide, electrolysis of a sodium chloride solution leads to the formation of sodium hydroxide at the cathode, along with the generation of chlorine gas at the anode and hydrogen gas at the cathode. The main difference in the preparation lies in the raw materials used, with potassium hydroxide production relying on potassium - containing salts and sodium hydroxide production on sodium - containing salts.

Applications

In Chemical Manufacturing

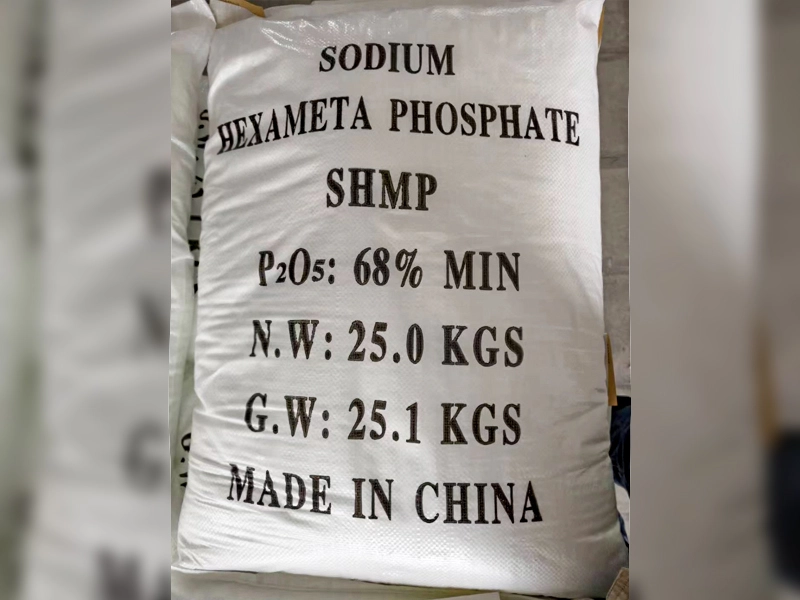

In chemical manufacturing, potassium hydroxide is widely used in the production of potassium - based chemicals such as potassium phosphates, which are important fertilizers. It is also employed in the synthesis of certain polymers and as a catalyst in some organic reactions. Sodium hydroxide, on the other hand, is a key ingredient in the production of soaps and detergents. Through a process called saponification, it reacts with fats and oils to produce soap molecules and glycerol. Additionally, it is used in the manufacturing of paper, where it helps in the pulping process to break down lignin, separating cellulose fibers for paper production.

In Electroplating and Metal Processing

Potassium hydroxide finds application in electroplating baths, particularly for plating certain metals like zinc. Its ability to dissolve metal oxides and maintain an alkaline environment is beneficial for achieving a smooth and uniform metal coating. Sodium hydroxide is used in metal cleaning and surface treatment processes. It can remove grease, oils, and rust from metal surfaces, preparing them for further processing such as painting or plating.

In Food and Consumer Products

Potassium hydroxide has limited but specific uses in the food industry. For example, it can be used in the production of cocoa to adjust the pH, affecting the flavor and color of the final product. It is also used in the production of soft pretzels to create the characteristic chewy texture. Sodium hydroxide, on the other hand, is used in the processing of olives to remove their bitterness. It is also used in the production of some food - grade thickeners and stabilizers.

Safety and Handling

Both potassium hydroxide and sodium hydroxide are highly corrosive substances. They can cause severe burns to the skin, eyes, and respiratory tract upon contact. When handling these chemicals, appropriate personal protective equipment (PPE) such as gloves, goggles, and lab coats must be worn. In case of contact with skin or eyes, immediate and prolonged flushing with plenty of water is essential. However, due to the differences in their reactivity and solubility, the nature of the potential hazards may vary slightly. For instance, potassium hydroxide's higher solubility in some solvents means that it can spread more rapidly in certain environments, increasing the risk of accidental exposure in some cases.

In conclusion, while potassium hydroxide and sodium hydroxide share the common trait of being strong bases, their differences in chemical and physical properties, preparation methods, applications, and safety considerations make them suitable for distinct purposes. Understanding these differences is crucial for chemists, engineers, and industrial workers to utilize these chemicals effectively and safely in a wide range of applications.

- Random Content

- Hot content

- Hot review content

- Industrial concentrated nitric acid 55%-68%

- Plastic Shock Tube(VOD≧1600m/s)

- Calcium Peroxide 60% Assay Yellowish Tablet

- Antimonium Tartrate Potassium

- Food Grade Heavy Light Precipitated Calcium Carbonate Powder Granular 99%

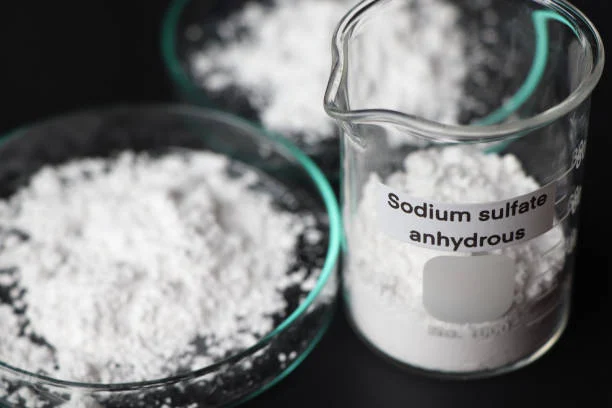

- Sodium sulphate 99% Pharmacy Grade

- 2-Hydroxyethyl acrylate (HEA)

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3 High-Quality Sodium Cyanide for Leaching

- 4Powdery emulsion explosive

- 5Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- 6Colloidal emulsion explosive

- 7sodium hydrosulfide 70% flakes used Mining Industry

Online message consultation

Add comment: